The Production Readiness Review (PRR) assesses a program to determine if the design is ready for production. It evaluates if the prime contractor and major subcontractors have accomplished adequate production planning without incurring unacceptable risks that will breach thresholds of schedule, performance, cost, or other established criteria.

Definition: The Production Readiness Review (PRR) determines if a systems design is ready for production and if the system developer has accomplished adequate production planning to enter Low-Rate Initial Production (LRIP) and Full-Rate Production (FRP).

Production Readiness Review (PRR) Purpose

The purpose of the PRR is to evaluate the full, production-configured system to determine if it correctly and completely implements all system requirements. The review determines whether the traceability of the final system requirements to the final production system is maintained. A successful review is predicated on determining that the system requirements are fully met in the final production configuration and that production capability forms a satisfactory basis for proceeding into Low-Rate Initial Production (LRIP) and Full-Rate Production (FRP).

When to Conduct a Production Readiness Review (PRR)

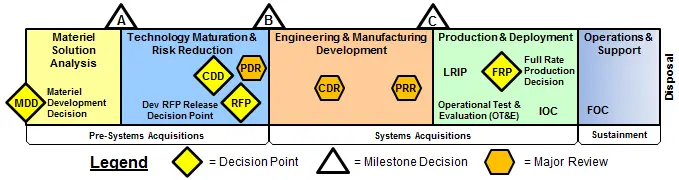

PRRs are normally performed as a series of reviews toward the end of the Engineering, Manufacturing, and Development (EMD) Phase. During System Capability and Manufacturing Process Demonstration, they should be conducted to identify and mitigate risks as the design progresses.

Production Readiness Review (PRR) Review Areas

The following areas of interest should be reviewed during a PRR:

- The manufacturing readiness process

- Quality management system

- Production planning

- System requirements compliance

- Inventory management

- Supplier management

Production Readiness Review Key References

Checklist: Production Readiness Review Checklist

Questions: Production Readiness Review Questions

Reference: Defense Acquisition Guidebook (DAG) – Chapter 3.7

Production Readiness Review (PRR) Questions

A few of the key questions that need to be answered during a PRR are:

- Has the system product baseline been established and documented to enable the system to be produced?

- Has a good configuration control process been established?

- Are adequate processes and metrics in place?

- Have the risks been documented and manageable?

- Has the production capability forms been a satisfactory basis for proceeding into Low-Rate Initial Production (LRIP) and Full-Rate Production (FRP)?

- Can the system be produced within the allocated production budget?

Production Readiness Review (PRR) Completion

The Technical Review Chair determines the successful completion of the PRR. The results of the PRR and associated manufacturing readiness assessments are typically documented in a written report or out-brief. The results should be reported based on the criteria documented in the Systems Engineering Plan (SEP), using the PRR checklist.

Follow-on Production Readiness Review (PRR)

A follow-on PRR may be appropriate in the Production and Deployment (PD) phase for the prime contractor and major subcontractors if: [1]

- Any changes from the Engineering and Manufacturing Development (EMD) phase system design in materials and/or manufacturing processes are required when entering or during the Production and Deployment (P&D) phase.

- Production start-up or re-start occurs after a significant shutdown period.

- Production start-up is with a new contractor

- The manufacturing site is relocated

Technical Review Standards

IEEE 5288.2 “Standard for Technical Reviews and Audits on Defense Programs” is the standard for technical reviews and audits to be performed throughout the acquisition life cycle for the US Department of Defense (DoD) and other defense agencies. This standard guides the DoD and contractor on what is required during a PRR.

AcqNotes Tutorial

Production Readiness Review (PRR) Roles and Responsibilities

The unique Program Manager (PM) responsibilities associated with a system PRR include: [1]

- Approving, funding and staffing the PRR as planned in the Systems Engineering Plan (SEP) developed by the Systems Engineer.

- Establishing the plan to Physical Configuration Audit (PCA) in applicable contract documents, including the SE Management Plan (SEMP), Integrated Master Schedule (IMS), and Integrated Master Plan (IMP).

- Ensuring the plan includes subject matter experts to participate in each review.

- Determining if the readiness of manufacturing processes, quality management system, and production planning (i.e., facilities, tooling, and test equipment capacity, personnel development and certification, process documentation, inventory management, supplier management, etc.) provide low-risk assurances for supporting LRIP and FRP.

- Continuing to control appropriate changes to the product baseline (see CH 3–4.1.6. Configuration Management Process)

The unique Systems Engineer responsibilities associated with a system PRR include: [1]

- Developing and executing the PRR plans with established quantifiable review criteria, carefully tailored to satisfy program objectives.

- Ensuring the pre-established review criteria have been met ensures the production capability forms a satisfactory, affordable, and sustainable basis for proceeding into LRIP and FRP.

- Advising the PM on whether production capability forms a satisfactory, affordable, and sustainable basis for proceeding into LRIP and FRP.

- Ensuring adequate plans and resources are in place to proceed from PRR to PCA and FRP Decision Review (DR).

- Ensuring plans to proceed to PCA and FRP DR allow for contingencies.

- Ensuring production implementation supports overall performance and maintainability requirements.

- Monitoring and controlling the execution of the PRR closure plans.

AcqLinks and References:

- Production Readiness Review Questions

- [1] Defense Acquisition Guidebook (DAG) – Chapter 3

- Production Readiness Review Checklist

- Production Readiness Review Checklist (PDF Version)

- Test and Evaluation Management Guide – Chapter 12.3

- NAVAIR Instruction 4355.19D – Systems Engineering Technical Review

- OSD Guide to Best Practices Using Engineering Standards – April 2017

- IEEE 15288.2 “Standard for Technical Reviews and Audits on Defense Programs

Updated: 2/20/2024

Rank: G4.3