A Critical Design Review (CDR) is a multi-disciplined independent technical assessment to ensure that a system can proceed into fabrication, demonstration, and test and meet stated performance requirements within cost, schedule, and risk. A successful CDR is predicated upon a determination that the detailed design satisfies the Capabilities Development Document (CDD). Multiple CDRs may be held for key Configuration Items (CI) and/or at each subsystem level, culminating in a system-level CDR.

Definition: “The Critical Design Review (CDR) is a multi-disciplined technical review that establishes the initial product baseline. A successful CDR is predicated on the determination that the subsystem requirements, subsystem detailed designs, results of peer reviews, and plans for test and evaluation form a satisfactory basis for proceeding into system implementation and integration”

Critical Design Review (CDR) Reference

The CDR fact sheet is designed as a technical review preparation tool and should be used as a guide for assessing risk during the review.

Fact Sheet: Critical Design Review Fact Sheet

Checklist: DoD Critical Design Review (CDR)

Purpose of the Critical Design Review (CDR)

The purpose of a CDR is to assess a system’s final design as captured in product specifications for each Configuration Item in the system’s product baseline and ensure that each configuration item has been captured in the detailed design documentation. The resulting set of detailed drawings and specifications establish an initial product baseline, with a final baseline incorporating any design changes resulting from System Demonstration and Initial Operational Test and Evaluation (IOT&E).

Completion of the Critical Design Review (CDR)

The completion of CDR usually initiates the start of formal Configuration Management (CM) by the Contractor of the Technical Baseline. Any changes to that baseline can only be accomplished with the approval of the Government.

Critical Design Review (CDR) Product Baseline [2]

The CDR should be conducted when the Product Baseline has been achieved, allowing the fabrication of hardware and coding of software deliverables to proceed. A rule of thumb is that 75 percent to 90 percent of (manufacturing quality) product drawings, software design specification(s), and associated instructions should be complete and that 100 percent of all safety-critical components (Critical Safety Items and Critical Application Items) drawings are complete. It is traceable to the system performance requirements contained in the Capability Development Document (CDD).

What is the Product Baseline

The product baseline describes the detailed design for production, fielding/deployment, and operations and support. The product baseline prescribes all necessary physical (form, fit, and function) characteristics and selected functional characteristics designated for production acceptance testing and production test requirements. It is traceable to the system performance requirements contained in the CDD.

When is the Critical Design Review (CDR) Conducted

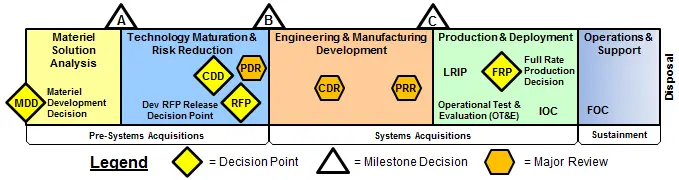

The CDR is conducted during the Engineering, Manufacturing, and Development (EMD) phase and when the product baseline has been achieved, and the CDR entrance criteria detailed in the Systems Engineering Plan (SEP) have been met, allowing fabrication of hardware and coding of software deliverables to proceed.

A Critical Design Review (CDR) should: [1]

- Determine that the detailed design of the configuration item under review satisfies cost (for cost-type contracts), schedule, and performance requirements.

- Establish detailed design compatibility among the configuration item and other equipment, facilities, computer software, and personnel items.

- Assess configuration item risk areas (on a technical, cost, and schedule basis).

- Assess the results of producibility analyses conducted on system hardware.

- Review preliminary hardware product specifications.

- Determine the acceptability of the detailed design, performance, and test characteristics and the adequacy of the operation and support documents.

Completion of Critical Design Review (CDR) should provide: [1]

- A system initial Product Baseline,

- An updated risk assessment for Engineering, Manufacturing, and Development (EMD),

- An updated Cost Analysis Requirements Description (CARD) based on the system product baseline,

- An updated program development schedule, including fabrication, test and evaluation, software coding, critical path drivers, and

- An approved Life-Cycle Sustainment Plan (LCSP) updating program sustainment development efforts and schedules based on current budgets, test evaluation results, and firm supportability design features.

Completed Critical Design Review (CDR) Reporting: [2]

The Program Manager shall provide a Post-CDR Report to the Milestone Decision Authority (MDA) that provides an overall assessment of design maturity and a summary of the system-level CDR results, which shall include, but not be limited to:

- The names, organizations, and areas of expertise of independent subject matter expert participants and CDR chair,

- A description of the product baseline for the system and the percentage of build-to packages completed for this baseline,

- A summary of the issues and actions identified at the review, together with their closure plans,

- An assessment of risk by the participants against the exit criteria for the EMD phase, and

- Identification of those issues/risks that could result in a breach of the program baseline or substantively impact cost, schedule, or performance.

Post-Critical Design Review (CDR) Assessment

For Major Defense Acquisition Programs (MDAP), the Deputy Assistant Secretary of Defense (Systems Engineering) “DASD(SE)” will assess the design maturity and technical risks evident in the CDR. Program Managers (PM) of these programs are required to invite DASD(SE) engineers to their system-level CDRs and make available CDR artifacts. These will include all CDR briefings and those artifacts that constitute the initial product baseline. [1]

Difference Between Critical Design Review (CDR) and Preliminary Design Review (PDR)

Where a CDR is focused on determining if a system can meet its stated performance requirements within cost, schedule, and risk. A Preliminary Design Review (PDR) is conducted to ensure new technologies are mature enough to be integrated into a product subsystem to form its allocated baseline.

AcqNotes Tutorial

AcqTips:

- The CDR chairperson should tailor the review to the technical scope and risk of the system and address specifics of the CDR in the Systems Engineering Plan (SEP).

- IEEE 15288.2 “Standard for Technical Reviews and Audits on Defense Programs” is the standard for technical reviews and audits to be performed throughout the acquisition life cycle for the US Department of Defense (DoD) and other defense agencies. This standard guides the DoD and contractor on what is required during a CDR

- See Major Reviews

AcqLinks and References:

- [1] Defense Acquisition Guidebook (DAG) – Chapter 4

- [2] Fact Sheet: Critical Design Review Fact Sheet

- Checklist: DoD Critical Design Review (CDR Checklist

- Critical Design Review (CDR) Questions

Update: 2/8/2024

Rank: G3.2