Value Engineering (VE) (FAR Part 48) is an organized/systematic approach that analyzes the functions of systems, equipment, facilities, services, and supplies to ensure they achieve their essential functions at the lowest Life-Cycle Cost (LCC) consistent with required performance, reliability, quality, and safety. Typically the implementation of the VE process increases performance, reliability, quality, safety, durability, effectiveness, or other desirable characteristics. [1]

Definition: Value engineering is an analytical tool to meeting the necessary functions of a project for the lowest life cycle cost.

Value Engineering Equation: Value = Function / Cost

VE is a management tool that can be used alone or with other management techniques and methodologies to improve operations and reduce costs. For example, the acquisition reform efforts, the emphasis on performance-based specifications, the design-build project delivery process, and the use of Integrated Product Teams (IPT) can include VE and other cost-reduction techniques, such as life-cycle costing, Cost As an Independent Variable (CAIV), concurrent engineering, and design-to-cost approaches. These techniques are effective as analytical tools in process and product improvement. VE can be used with Lean-Six Sigma processes to challenge requirements and identify functions that cost more than they are worth. [1]

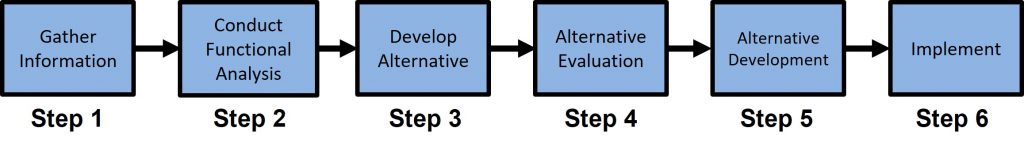

Conducting Value Engineering (VE) Analysis and Steps

Conducting a Value Engineering analysis consist of six steps. The analysis is usually accomplished in the design phase of a product but can be conducted at any time in the development and production of a product. The six steps are.

- Step 1: Gather Information: obtain project information

- Step 2: Conduct a Functional Analysis: determine the key functions of the product or project

- Step 3: Develop Actionable Alternatives: Generating alternative solutions which accomplish the intended functions but add value.

- Step 4: Alternative Evaluation: Develop a list of solutions worth implementing

- Step 5: Alternative Development: Develop the alternatives into an actionable plan

- Step 6: Implement: Implement the new alternative

Value Engineering Change Proposal (VECP)

Value Engineering Change Proposal (VECP) is a proposal submitted by a contractor under the Value Engineering (VE) provisions of the Federal Acquisition Regulation (FAR) (FAR Part 48) that, through a change in the contract, would lower the project’s life-cycle cost to DoD. It’s intended to reduce costs, increase quality, and improve mission capabilities across the entire spectrum of DoD systems, processes, and organizations.

Value Engineering (VE) Program

The DoD Value Engineering Program is set up to guide and monitor VE initiative in the DoD. They also help monitor the Value Engineering Change Proposal (VECP) rules and procedures. The program has two (2) distinct components:

- An in-house effort performed by DOD military and civilian personnel; and

- An external effort performed by DOD contractors and applied to contracts after Department approval.

The VE Management Advisory Group (VEMAG) is established to act as the agent across Services and agencies promoting the use of value engineering. The chair of the VEMAG is the Office of the Secretary of Defense (OSD) VE Program Manager (PM). The membership consists of one primary voting member from each Service and agency. [1]

Public Law

In the United States, value engineering is specifically spelled out in Public Law 104-106, which states “Each executive agency shall establish and maintain cost-effective value engineering procedures and processes.”

Federal Acquisition Regulation (FAR)

FAR Part 48 “Value Engineering” governs VE within the Federal Government. According to FAR 48.201(a), unless exempted by an agency head, a VE incentive clause must be included in all contracts exceeding $100,000 except those for research and development (other than full-scale development), engineering services for non-profit organizations, personal services, commercial items, or limited specific product development. Furthermore, the use of the VE incentive clause is encouraged for use in smaller dollar-value contracts where there is a reasonable chance for acquisition savings. For supplies or services contracts, FAR 52.248-1 “Value Engineering” is the incentive clause that provides the basis for contractors to submit Value Engineering Change Proposals (VECP). [2]

History of Value Engineering (VE)

Value engineering started at General Electric in the middle of World War II. It was started by purchase engineer Lawrence Miles who needed to find cheaper substitutes for materials due to a shortage of these materials that were being used. These substituted materials he found often provided the same benefits at a lower cost. So value engineering was born.

AcqTips:

- Program Managers (PM) should push Value Engineering Change Proposals made by contractors as a way of sharing cost savings and should also ensure that implementation decisions are made promptly.

AcqLinks and References:

- [1] SD-24 Value Engineering: A Guidebook of Best Practices and Tools

- [2] IDA – Value Engineering Change Proposals in Supplies or Services Contracts by Jay Mandelbaum

- Website: DoD Value Engineering Program

- Website: Wikipedia – Value Engineering

- Website: FAR 52.248-1 – Value Engineering Provisions and Clauses

- Website: FAR 48.201 – Clauses for Supply or Service Contract

Updated: 7/25/2021

Rank: G24.1