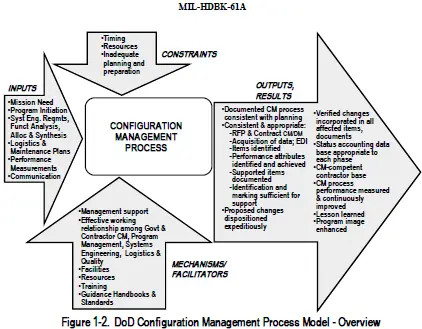

Configuration Management (CM) is the application of sound program practices to establish and maintain consistency of a product’s or system’s attributes with its requirements and evolving technical baseline over its life. It involves interaction among government and contractor program functions such as systems engineering, hardware/software engineering, specialty engineering, logistics, contracting, and production in an Integrated Product Team (IPT) environment.

Definition: Configuration Management (CM) is a systems engineering process for establishing and maintaining consistency of a product’s performance, functional, and physical attributes with its requirements, design, and operational information throughout its life. (MIL-HDBK-61A)

Main Guide: MIL-HDBK-61A “Configuration Management Guidance”

Configuration Management (CM) Responsibility

The Program Manager (PM) is responsible for Configuration Management (CM) on their project or program. The program manager should use configuration management to establish and mature the technical, functional, and Acquisition Program Baseline throughout the acquisition and system life cycle. [1]

The Program Manager shall assume control of the initial product baseline at the Critical Design Review (CDR) for all Class 1 configuration changes.

Configuration Management Activities

The main CM activities include:

- Identifying, defining, and baselining configuration items

- Controlling modifications and releases of configuration items

- Reporting and recording status of configuration items and any requested modifications

- Ensuring completeness, consistency, and correctness of configuration items

- Controlling storage, handling, and delivery of the configuration

Benefits of Configuration Management (CM)

Effective CM provides the following essential benefits to a project:

- Reduces confusion and establishes order

- Organizes the activities necessary to maintain product integrity

- Ensures correct product configurations

- Limits legal liability by providing a record of actions

- Reduces lifecycle costs

- Enables consistent conformance with requirements

- Enhances compliance with standards

Configuration Management Plan

The overall objective of the Configuration Management Plan is to document and inform project stakeholders about Configuration Management (CM) within a project, what CM tools will be used, and how they will be applied by the project. The CM Plan details the methodology that the Program Manager (PM) and systems engineer will be used to control program documentation and the program baseline (Technical, Functional, and Allocated).

Configuration Management (CM) Baselines

A Configuration Baseline is the performance documentation and specifications that make up a product during its development at a specific time. The baseline is used to track, monitor, and manage changes throughout the development life-cycle.

The Configuration Baseline is established for specific events in a program’s life-cycle and contributes to the performance portion of a program’s Acquisition Program Baseline (APB). The overall Technical Baseline rolls up into the APB and consists of the following configuration baselines:

- Functional Baseline

- Allocated Baseline

- Product Baseline

Configuration Management Information System

The DoD Configuration Management Information System (CMIS) supports the configuration, engineering, and technical data management functions of the Department of Defense (DoD) community with a standard Web-Based Automated Information System (AIS).

Interface Management

Interface Management identifies, develops, and maintains the external and internal interfaces necessary for system operation. It supports control measures (Configuration Management) to ensure that all internal and external interface requirement changes are properly documented in accordance with the configuration management plan and communicated to all affected configuration items.

Configuration Management History

CM was first developed by the United States Air Force for the Department of Defense in the 1950s as a technical management discipline of hardware. The concepts of this discipline have been widely adopted by numerous technical management functions, including Systems Engineering (SE), Integrated Logistics Support (ILS), Capability Maturity Model Integration (CMMI), ISO 9000, Prince2 project management methodology, COBIT, Information Technology Infrastructure Library (ITIL), product lifecycle management, and application lifecycle management. [1]

AcqNotes Tutorial

AcqLinks and References:

- [1] Defense Acquisition Guidebook (DAG)

- [2] Website: Wikipedia – Configuration Management

- MIL-HDBK-61A “Configuration Management Guidance” – 7 February 2001

- MIL-STD-1916, “DOD Preferred Methods for Acceptance of Product”

- NAVAIR Configuration Management Policy Manual – 21 Dec 2016

- Navy Configuration Management Advisor

- IEEE Guide to Software Configuration Management

- Department of Health Practices Guide Institute of Configuration Management

- Sun Microsystems Best Practices in Configuration Management

- Introduction to Software Configuration Management Training Briefing

- GSA Acquisition Manual “Configuration Management” – Chapter 9

- Little book of Configuration Management

- Website: ANSI/EIA-649″National Consensus Standard for Configuration Management” (Available for Purchase)

Updated: 12/18/2021

Rank: G61.5