The Critical Chain Method (CCM) is used to perform Schedule Network Analysis that considers task dependencies, limited resource availability, and buffers. It’s used to prepare the project schedule when limited or restricted resources are available. In this method, the Program Manager (PM) usually schedules all or most high-risk or critical activities in the earlier stage of the project schedule. This allows the critical tasks to be completed early and gives buffers to handle unexpected problems if they arise. Also, the PM will combine several tasks into one task and assign one resource to handle all.

Definition: The Critical Chain Method (CCM) is a project management technique that focuses on resource availability and constraints, rather than task dependencies, to determine the critical path of a project. The critical chain method aims to reduce project duration and avoid resource conflicts by using buffers and resource-leveling strategies.

Critical Chain Method (CCM) Goal

The Critical Chain Method (CCM) aims to eliminate project schedule delays due to uncertainties, overestimating task duration and wasted internal buffers.

Benefits of the Critical Chain Method (CCM)

The critical chain method is more effective than the critical path method in several important ways. Among these ways are:

- The critical chain method gives all of a project’s resources to it. So, if a task is done early, you can move on to the next one without hitting any snags.

- The project manager is in charge of managing the buffer, not the team. It is up to the team to finish their tasks within the estimated time frame.

Utilizing the Critical Chain Method (CCM) in Your Schedule

To develop a project schedule using the critical chain method, you do the following:

- Define Activities: What needs to be done to finish the project?

- Estimate task durations: How long does each task take to finish?

- Calculate Buffer: Make plans for what could go wrong based on who is doing the work and how much time they have to spend on the project.

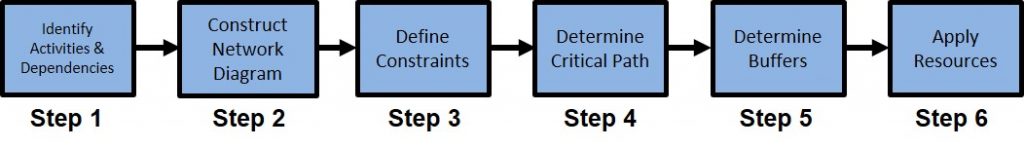

Critical Chain Method (CCM) Development Steps

The six (6) steps involved in the development of the CCM are:

- Step 1: Identify all activities and dependencies

- Step 2: Construct a Schedule Network Diagram

- Step 3: Define constraints

- Step 4: Determine the critical path

- Step 5: Determine buffers

- Step 6: Apply resource availability

Critical Chain Method (CCM) Buffers

A Buffer is an extra time added to a plan/schedule so that a task can be done and delays can be considered. The CCM has three (3) different types of Buffers, which are:

- Resource buffer: is inserted just before a critical chain activity where a critical resource is required. It’s used to remind the project team that a resource is needed and to finish up prior activities.

- Feeding buffer: is inserted as a safety margin in the non-critical chain of a network schedule. It’s placed where the path feeds back into the critical chain path.

- Project buffer: the summation of all the internal buffers added to each project task or activity.

Example of the Critical Chain Method (CCM) for Building a Backyard Deck

The Critical Chain Method (CCM) is a project management technique that focuses on resource availability and constraints, rather than task dependencies, to determine the critical path of a project¹. The CCM aims to reduce project duration and avoid resource conflicts by using buffers and resource leveling strategies².

To use the CCM for building a backyard deck, you need to follow these steps:

- Step 1: List all the activities or tasks required to complete the project, such as measuring, cutting, assembling, painting, etc.

- Step 2: Estimate the duration of each activity or task, based on the resources available and the complexity of the work. Use realistic estimates without adding any safety or buffer time.

- Step 3: Identify the resources needed for each activity or task, such as people, materials, equipment, etc. Consider the availability and capacity of each resource and how they are shared among different tasks or projects.

- Step 4: Draw a network diagram that shows the sequence and dependencies of the activities or tasks, using nodes to represent activities and arrows to represent dependencies. Use resource leveling techniques to avoid overloading or underutilizing any resource. Depending on the availability of resources, this may involve shifting some tasks to start later or finish earlier.

- Step 5: Identify the critical chain, the longest path in the network diagram that considers both task dependencies and resource constraints. The critical chain determines the minimum completion time of the project and any delay in any activity on this path will delay the entire project.

- Step 6: Add buffers to protect the critical chain from uncertainties and variations. There are three types of buffers in CCM: project buffer, feeding buffer, and resource buffer.

- Project buffer: This is a time cushion added at the end of the critical chain to protect the project completion date from any delays or risks along the critical chain. The size of the project buffer is usually calculated as a percentage of the total duration of the critical chain (e.g., 25%).

- Feeding buffer: This is a time cushion added at each point where a non-critical chain (or a feeding chain) merges with the critical chain. The purpose of the feeding buffer is to prevent any delays in the non-critical chains from affecting the critical chain. The size of the feeding buffer is usually calculated as a percentage of the total duration of the feeding chain (e.g., 50%).

- Resource buffer: This is a time cushion added before each activity on the critical chain that requires a scarce or critical resource. The purpose of the resource buffer is to ensure that the resource is available and ready when needed for critical activity. The resource buffer’s size depends on the resource’s availability and demand.

Here is an example of using the CCM for building a backyard deck:

| Activity | Description | Duration | Predecessors | Resources |

| A | Measure and mark the deck area | 1 Hour | None | Carpenter |

| B | Dig holes for post | 2 Hours | A | Carpenter, Digger |

| C | Cut posts to size | 1 Hour | None | Carpenter, Saw |

| D | Set posts in concrete | 3 Hours | B, C | Carpenter, Mixer |

| E | Cut Joists and beams | 2 Hours | None | Carpenter, Saw |

| F | Attach joist and beams to posts | 4 Hours | D, E | Carpenter, Drill |

| G | Cut and install decking boards | 6 Hours | F | Carpenter, Saw, Drill |

| H | Sand and stain the deck | 4 Hours | G | Painter |

The critical chain for this example is A-B-D-F-G-H, with a minimum completion time of 20 hours without buffers. Any delay in any of these activities will delay the entire project. The activities C and E are not on the critical chain and have some flexibility in their scheduling.

The project buffer is added at the end of the critical chain and has a size of 25% of 20 hours, which is 5 hours. The feeding buffer is added at point D where activity E merges with the critical chain and has a size of 50% of 2 hours, which is 1 hour. The resource buffers are added before activities B, C, D, E, F, G, and H because they all require either a carpenter or saw or both, which are scarce resources. The size of each resource buffer depends on how much time it takes to secure or release these resources.

The total project duration with buffers is 26 hours. The project manager can monitor the consumption of the buffers and take corrective actions if needed to keep the project on track.

Difference Between Critical Chain Method (CCM) and Critical Path Method (CPM)

There are a few differences between the critical chain and the critical path methods, but they both focus on schedule development and estimation. These are:

- Critical Path Method is focused on how long a project is based on task estimation and the amount of float on a project.

- Critical Chain Method operates on shortening how long a project is due to overestimation, uncertainties, and buffers.

AcqLinks and References:

- [1] Defense Systems Management College “Scheduling Guide for Program Managers” – Oct 2001

- DoD “Integrated Master Plan and Integrated Master Schedule Preparation and User Guide” – 21 Oct 2005

- CDC “Project Scheduling Best Practices/Guide” – 30 Jun 2007

- GAO 12-120G “Schedule Assessment Guide: Best Practices for Project Schedule” – May 2012

Updated: 7/13/2023

Rank: G2.9