Verification and Validation (V&V) are steps to determine whether a system or component satisfies its operational and system-level requirements. V&V requirements are established during a program to provide adequate direction for system engineers to gauge the program’s progress.

- Verification is a quality control process that determines whether a system meets its system-level requirements. Inspection and demonstration are the main testing methods used in the Verification process. Are we building the product right?

- Validation is a quality control process that determines if operational requirements are met for the overall system to meet the Initial Capabilities Document (ICD) and Capability Development Document (CDD). The analysis is a testing method primarily used in Validation. Are we building the right product?

Definition: Verification and Validation (V&V) are independent methods and procedures that are used to check if a component, product, service, or system meets its established requirements and specifications and that it satisfies its intended overall purpose.

Purpose of Verification and Validation (V&V)

The purpose of V&V is to provide direct evidence of progress toward ultimately meeting the customer’s requirements. The V&V results ensure that the product will pass the customer’s criteria. Eventually, these results prove that the product performs as specified and indicate how well it will satisfy its operational needs. [1]

Benefits of Verification and Validation (V&V)

Verification and validation are critical parts of product creation in many fields. Here are some of the most essential benefits of checking and confirming:

- Making sure the product works: Verification and validation help ensure the product works how it’s supposed to and meets the standards. By systematically testing and evaluating the product, possible design flaws, defects, or performance problems can be found and fixed, making the final product more useful and reliable.

- Improving the quality of the product: Thorough testing and validation can improve the quality of the product. Finding problems early in the development process and fixing them increases the chances of making a high-quality product that meets customer standards.

- Minimizing costs and risks: Verification and validation help reduce the risks of product fails or problems with how it works. By finding and fixing possible problems early on, the costs and effects of recalls, insurance claims, and unhappy customers can be kept to a minimum. This saves money for the group and keeps its reputation in good shape.

- Meeting rules and standards: Verification and validation ensure that the product meets the rules and standards set by the government and the business. By thoroughly testing the product against relevant requirements and regulations, organizations can show compliance, meet legal obligations, and avoid fines or other legal liabilities.

- Improving customer satisfaction: Organizations can deliver products that meet or exceed customer standards if they do thorough verification and validation. This makes customers happier, keeps them returning, and gives the brand a good name. Customers who are happy with the product are likelier to buy it again and tell their friends about it.

- Improving performance and efficiency: The actions of verification and validation help improve the performance and efficiency of the product. By testing and tweaking things like functionality, usability, speed, and dependability, companies can improve the overall performance of their products and gain a competitive edge in the market.

- Helping with continuous improvement: The verification and validation methods give useful feedback and data that can be used to drive efforts to keep getting better. Testing and validation help find places to improve, guide future design changes, and give product developers information they can use to make decisions.

- Improving safety and reliability: Verification and approval are crucial for ensuring a safe and reliable product. By putting the product through many tests, like safety checks and tests to see how reliable it is, possible problems or risks can be found and fixed. This makes the goods safer for those who use them and reduces the chances of accidents or failures.

Verification Process

The verification process confirms that a system element meets design-to or build-to specifications. Throughout the system’s life cycle, design solutions at all levels of the physical architecture are verified through a cost-effective combination of analysis, examination, demonstration, and testing, all of which can be aided by modeling and simulation. [1]

The following are verification’s key benefits:

- At every level of the product development process, it serves as quality control.

- It makes it possible for product teams to create products that satisfy both design requirements and consumer needs.

- By identifying the flaws early on in the development process, time is saved.

- Defects that could occur later in the development process are decreased or eliminated.

Verification Example for Race Car Development

Verification checks whether the racing car has been designed and built correctly according to the specified requirements and standards. Here are some verification activities in the context of developing a racing car:

- Design reviews: The design team conducts thorough reviews of the car’s design, including its aerodynamics, chassis, suspension, engine, and safety features. They verify that the design meets the desired performance goals and complies with regulations.

- Component testing: Each critical component of the racing car, such as the engine, brakes, transmission, and suspension, undergoes rigorous testing. This includes bench testing, computer simulations, and physical prototypes to ensure they function as intended and meet performance specifications.

- Wind tunnel testing: The car’s aerodynamics are verified through wind tunnel testing. It helps evaluate the car’s downforce, drag, and overall stability at different speeds to optimize its performance on the track.

- Safety assessments: The racing car undergoes comprehensive safety assessments to verify that it meets the necessary safety standards and regulations. Crash tests, fire resistance tests, and driver safety evaluations are performed to ensure the car adequately protects the driver.

Validation Process

The Validation Process answers the question of, “Is it the right solution to the problem?” This process works in conjunction with the Stakeholder Requirements, Requirements Analysis, and Architecture and Design processes. It evaluates the requirements, functional and physical architectures, and implementation. In the early stages of the system development life cycle, validation may involve independent evaluation of the system requirements, development of prototypes, and simulations, all to validate the system concept.

Three (3) processes encompass validation: [1]

- Review documentation by an operational authority other than the user to confirm the operational capability. Validation is the precursor to approval.

- The process by which the contractor tests a publication/technical manual for technical accuracy and adequacy.

- The process of evaluating a system or software component during, or at the end of, the development process to determine whether it satisfies specified requirements.

Validation Example for Race Car Development

Validation focuses on evaluating whether the racing car meets the expectations and requirements of its intended use. It involves testing the car in realistic scenarios to ensure its performance and reliability. Here are some validation activities:

- Track testing: The racing car is taken to the track, undergoing extensive testing under various conditions. Professional drivers put the car through its paces, assessing its handling, acceleration, braking, and overall performance. Data is collected and analyzed to validate the car’s behavior and make necessary adjustments.

- Endurance testing: The racing car is subjected to prolonged periods of running on the track to simulate race conditions. This helps validate the car’s durability, reliability, and performance over long distances and continuous use.

- Performance benchmarking: The racing car is compared against competitors or previous models to validate its performance improvements. Testing against known benchmarks helps determine whether the car achieves the desired speed, lap times, and overall competitiveness.

- Simulated races: The racing car may undergo simulated race scenarios in a controlled environment or through computer simulations. This helps validate its performance and reliability under competitive conditions, including overtaking, cornering, and strategic decision-making.

Difference Between Verification and Validation

The main difference between verification and validation is that Verification focuses on ensuring system-level requirements are met. In contrast, Validation focuses on ensuring the system performs the way it was designed and intended.

- Verification process includes checking documents, design, code, and program

- Validation process includes testing and validation of the actual product

- Verification uses methods like reviews, walkthroughs, inspections, and desk-checking

- Validation uses methods like models, box testing, and non-functional testing

- Verification checks whether a component (software) confirms a specification

- Validation checks whether a component (software) meets the requirements and expectations

- Verification comes before validation

Verification and Validation (V&V) in the Requirements Development Process

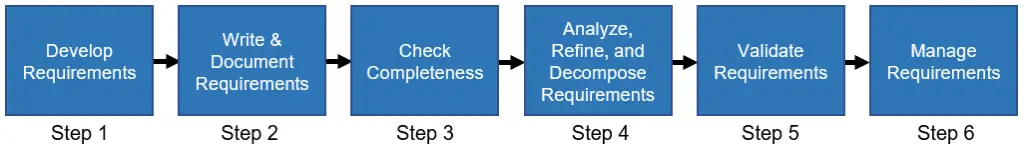

There are six (6) basic requirements development steps, and step 5 is to Verify and Validate requirements.

Below is a list of the basic six (6) steps of requirements development.

Requirements Development Steps

Step 5: Verify and Validate Requirements

In step five, each requirement must be verified and validated to ensure these are correct. This ensures that the requirements meet the overall objective of the system and all stakeholder needs.

AcqNotes Tutorial

Lessons Learned for Successful Verification and Validation (V&V)

Here are some tips and lessons that will help project managers and engineers do effective verification and validation testing:

- Start early: Start checking and validating as soon as possible in the building process. This lets problems be found and fixed quickly, lowering the chance of costly rework in the future.

- Clearly describe the requirements: Make sure the requirements for the racing car are clear and can be measured. Ensure that the standards are clear, reasonable, and in line with the project’s goals. Testing works best when the objectives are clear.

- Involve key stakeholders: During the verification and approval process, involve key stakeholders like designers, engineers, drivers, and safety experts. Their ideas and opinions can be constructive and help ensure that everything is considered.

- Use a risk-based approach: Put verification and validation attempts in order of how important they are and how likely they cause problems. Find the high-risk areas and spend more time trying those parts to find and fix problems before they start.

- Test in real-world conditions: Make test settings that are close to what racing conditions are like in the real world. This includes using tracks, weather, and driving behavior like the real world. Realistic testing gives more true information about how well the car works and how it acts.

- Combine different ways to test: Use a mix of ways to test, like physical tests, computer models, and modeling. Each method has its own pros and cons, and it’s best to use a variety of methods to get the most information.

- Write down and keep track of test results: Keep a complete record of all verification and validation activities, including test plans, methods, results, and observations. This documentation can be used as a guide for future versions and helps keep track of where things came from.

- Iterate and improve all the time: Think of checking and validating as ongoing processes. Learn from each testing run, determine what needs to be changed, and make those changes in the next iteration. This method makes the car run better and be more reliable generally.

- Work together and talk to each other well: Help project managers and engineers work together and talk to each other openly. Share progress reports, talk about problems, and ask for feedback often to make sure everyone is on the same page and decisions are made well.

- Keep a feedback process going: Set up ways to get feedback from drivers, team members, and other people interested in testing. Their ideas can be used to improve the race car’s design and fix any problems that might arise.

Using these tips, project managers and engineers can improve verification and validation testing, improving the racing car’s performance, safety, and total success.

AcqLinks and References:

- [1] SMC Systems Engineering Handbook – Chapter 7

- Modeling and Simulation Verification and Validation Challenges

- Picture: Verification Flow Chart from Chapter 7 of DAU SE Fundamentals Guide

Updated: 3/15/2024

Rank: G10.8