A Technical Performance Measurement (TPM) is a process that measures the risks inherent in a given project. It involves predicting the value of a critical technical performance parameter of the higher-level end product under development based on current assessments of products lower in the system structure. TPMs track and measure progress toward achieving the specified outcome after development. Continuously comparing the achievement of chosen technical parameters to expectations validates progress and reveals deviations that could jeopardize end product requirements. Values that are assessed and outside the defined tolerances call for management attention and corrective action. [2] [3]

Definition: A Technical Performance Measurement (TPM) is a technique that measures the risks inherent in a technical system element to determine how well that element is satisfying specified requirements. Regularly comparing actual achievement of chosen technical elements to expectations validates progress and reveals deviations that could put the fulfillment of end product requirement in jeopardy.

When are Technical Performance Measurements (TPM) Defined

At the start of a program, TPMs define the planned progress of selected technical parameters. The plan is defined in terms of expected performance at specific points in the program as defined in the Work Breakdown Structure (WBS) and Integrated Master Schedule (IMS), the methods of measurement at those points, and the variation limits for corrective action. [2] [3]

Purpose of Technical Performance Measurements (TPM)

The purpose of TPMs is to assess key capability values compared to those expected over time. TPM is an evolutionary Program Management and systems engineering tool that builds on the three parameters of (1) Earned Value Management (EVM) , (2) cost and schedule performance indicators, and (3) the status of technical achievement. By combining cost, schedule, and technical progress into one comprehensive management tool, program managers can assess the progress of their entire program. TPMs are typically established on those programs complex enough that the status of technical performance is not readily apparent. TPMs can also be valuable for Risk Tracking – levels below that forecast can indicate the need for an alternate approach.

Technical Performance Measurement (TPM) Example

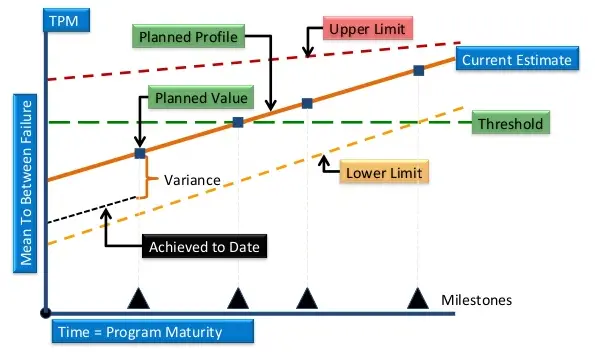

Below is an example of how a TPM is measured and displayed.

Figure: Example Technical Performance Measurement

Technical Performance Measurement (TPM) Evaluations

With a TPM program, it is possible to continuously verify the degree of anticipated and actual achievement of technical parameters and compare them with the anticipated value. TPM is also used to identify and flag deficiencies that might jeopardize meeting a critical system-level requirement. Measured values that fall outside an established tolerance band will alert management to take corrective action.

By tracking the system’s TPMs, the Program Manager and systems engineer determine whether the delivered system will meet its performance specifications (requirements). Beyond that, tracking TPMs ties together several basic systems engineering activities of Systems Analysis and Control, Functional Analysis Allocation, and Verification and Validation activities.

Developing Technical Performance Measurements (TPM)

TPMs are typically developed directly from Measures of Performance (MOP) to characterize physical or functional attributes relating to the execution of the mission or function. TPMs may also be derived from Measures of Effectiveness (MOE) to become system cost and effectiveness metrics. Some guidance for selecting TPMs:

- Performance parameters that significantly qualify the entire system

- Parameters are directly derived from analyses, demonstrations, or test

- A direct measure of value can be derived from the results of analyses or tests

- Predicted values have a basis (analyses, historical data)

- Each parameter can be measured and profiled periodically to compare with predicted values and tolerances over the project life cycle.

Selecting Appropriate Technical Performance Measurements (TPM)

The needs of the contractor and the government are often combined to determine the technical parameters to be tracked. Since the contractor requires information at a more granular level than the government program office does, the contractor typically keeps track of more things than are provided to the government. The government program office needs visibility into the technical performance of important WBS items, particularly those vital to the program’s success, cost drivers for the project, are on the critical path, or are high-risk items. The work breakdown structure is a great start when considering TPM tracking parameters.

Technical Performance Measurement (TPM) Hierarchy

The most important process in TPM planning is the development of the Technical Parameter Hierarchy, which requires the establishment of the Technical Performance Baseline. The technical performance baseline identifies all measurable key technical elements and establishes their relative relationships and importance. The hierarchy can represent the program, contract, sub-contract, or other subsets of technical requirements.

The hierarchy must comprehensively represent technical risk factors associated with the project. Typically, the highest level of the hierarchy represents system-level or operational requirements, with subsystem-level requirements underneath these as lower-level parameters. This form of TPM methodology serves internal tracking by the systems engineer and adds visibility to program status reporting.

AcqLinks and References:

- [1] SMC Systems Engineering Primer & Guide – Chapter 4

- [2] Defense Acquisition Guidebook (DAG)

- [3] EIA-632 “Processes for Engineering a System” – 7 Jan 99

- DAU Systems Engineering Fundamentals – Chapter 14

- Paper: Using Technical Performance Measures – 2011

- Report: INCOSE Technical Performance Measurements by Roedler and Jones – Dec 05

Updated: 4/9/2024

Rank: G2