Line of Balance (LOB) is a management control process for collecting, measuring, and presenting facts relating to time (see Schedule Control), cost, and accomplishment – all measured against a specific plan. It shows the process, status, background, timing, and phasing of the project activities, thus providing management with measuring tools that help:

- Comparing actual progress with a formal objective plan.

- Examining only the deviations from established plans and gauging their degree of severity concerning the remainder of the project.

- Receive timely information concerning trouble areas and indicate areas where appropriate corrective action is required.

- Forecasting future performance.

Definition: A Line of Balance (LOB) is a project management technique that visually represents the repetitive and sequential nature of work within a project by plotting it as a single line on a graph. This method helps in scheduling and tracking tasks that follow a consistent pattern, facilitating efficient resource allocation and project planning.

Purpose of Line of Balance (LOB)

The purpose of a LOB is to enable a program manager to see at a single glance which activities of a repetitive process operation are “in balance” – i.e., whether those which should have been completed at the time of the review actually are completed and whether any activities scheduled for future completion are lagging behind schedule. In other words, are we producing at a pace that allows an even flow of the items produced through a process and at a speed compatible with the goals outlined in a plan? The LOB chart comprises only one feature of the whole philosophy: numerous danger signal controls for all the various levels of management.

Benefits of Utilizing Line of Balance (LOB)

The benefits of using the LOB technique are:

- A better understanding of the amount of work taking place at a certain time in a specific place.

- Optimized resources for a large number of repeated work activities.

- Allows easier cost and time optimization analysis.

- Easy to modify, update and change the schedule.

- Better management of subcontractors and resources.

- Identifies issues in advance.

Line of Balance (LOB) Chart

A LOB chart shows the project work done repeatedly as a single line on a graph. It’s different from a bar chart, which shows how long an activity takes by showing the rate at which the job must be done to meet the limit and how each trade and process is related to the others. The progress of the project is shown along the x-axis. The project’s main work areas are shown along the y-axis. Each line on the chart represents a different activity. The slope of the line indicates the rate of progress for that activity. For example, a steep slope indicates the activity is progressing quickly, while a shallow slope indicates the activity is progressing slowly.

The chart also shows the planned and actual completion dates for each activity. The planned completion dates are shown as dashed lines, while the actual completion dates are shown as solid lines. The difference between the planned and actual completion dates represents the schedule variance.

Developing a Line of Balance (LOB) Chart

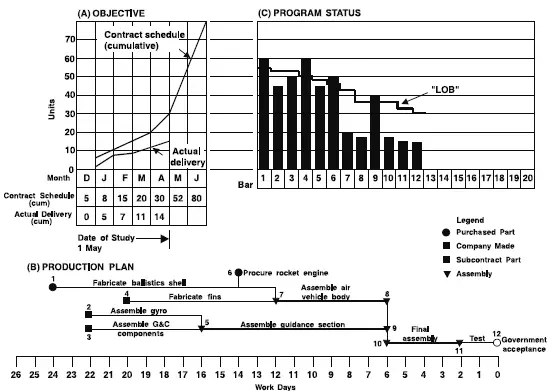

To do a LOB, the following is needed: [1]

- A contract schedule or objective chart;

- A production plan or lead-time chart for the production process itself;

- Control points cumulative inventories; and

- A program status chart on which to plot LOB and the cumulative quantities of units that have passed through the control points of the assembly/production process.

Example: Line of Balance Figure [1]

Remember that the shape of the LOB will change over time, especially if the production process has a beginning and an end. Remember, too, that LOB charts show where the problem is but not necessarily why the problem exists or what the solution is. [1]

When to use Line of Balance (LOB)

LOB is the most effective planning and scheduling technique for repetitive tasks such as track home construction, simple production, automobile manufacture, road construction, and railwork laying.

Line of Balance (LOB) History

The Goodyear Company created the LOB technique in the early 1940s before being adopted and developed by the U.S. Navy in the early-1950s. It was subsequently developed for industrial manufacturing, production control, and the basic concepts behind planning and scheduling in the construction industry.

Other Names used for Line of Balance (LOB)

The LOB is also known as the Repetitive Scheduling Method (RSM), Vertical Production Method, Location Based Scheduling, or Vertical Scheduling Method.

AcqLinks and References:

- [1] Defense System Management College “Scheduling Guide for Program Managers” – Oct 2001

- Article: PMI Scheduling Optimization with LOB and start-finish relations by Ricardo Viana Vargas, Felipe Fernandes Moreira – May 2015

Updated: 2/2/2024

Rank: G1