A Quality Management Plan (QMP) helps guide the Program Manager (PM) and project personnel to execute quality management and quality assurance activities for a project or program. The QMP is usually developed by a contractor and reviewed by the customer. Quality is the degree to which the project fulfills requirements.

Definition: A Quality Management Plan (QMP) documents the process for ensuring quality measure are implemented on a project by defining quality methodology, standards, criteria, activities, expectations, tools and resources, reporting and corrective actions. The QMP serves as the foundation for quality management on any project and addresses Quality Planning (QP), Quality Assurance (QA), Quality Control (QC), and Quality Improvemet (QI).

What is Quality Assurance

Quality Assurance (QA) is a monitoring approach that evaluates various aspects of an acquisition project or service to determine if the production process meets the minimum quality standards. QA includes regulation of the quality of raw materials, assemblies, products and components, services related to production, and management, production, and inspection processes. A QMP is part of an organization’s Quality Assurance.

Definition: Quality Assurance is the maintenance of a desired level of quality in a service or product, especially by means of attention to every stage of the process of delivery or production.

Purpose of Quality Management Plan (QMP)

The purpose of the QMP is to describe how quality will be managed throughout the project’s lifecycle. Quality management planning determines quality policies and procedures relevant to the project for project deliverables and processes, defines who is responsible for what, and documents compliance.

Why Have a Quality Management Plan (QMP)

Quality is a measure of providing products free from defects, deficiencies, and significant variations in the purchase-buyer transaction. High quality is brought about by the strict and consistent adherence to measurable and verifiable standards to achieve uniformity of output that satisfies specific customer or user requirements. This ensures that the best product is being developed and delivered to your customers. A good QMP will ensure the following:

- Customer expectations are met and satisfied

- Reduces cost of re-work

- Improves efficiency

- Ensures consistency

- Reduces cost!

Quality Management Plan (QMP) Tutorial

Components of a Quality Management System (QMS)

The practice of a quality management system is divided into four processes that are: Quality Planning (QP), Quality Assurance (QA), Quality Control (QC), and Quality Improvement (QI). Below is a quick explanation of each.

- Quality Planning (QP): is the foundation of our quality management system, encompassing the development of strategies and methodologies to meet customer expectations. This is the phase the QMP is developed.

- Quality Assurance (QA): is a monitoring approach that evaluates various aspects of an acquisition project or service to determine if the production process meets the minimum quality standards.

- Quality Control (QC): is a crucial component of our quality management system, focusing on the identification and correction of defects in products or processes.

- Quality Improvement (QI): is an ongoing effort to enhance processes, products, or services based on feedback, data analysis, and innovation.

Quality Management Plan (QMP) Key Components

The QMP must address Quality Planning (QP), Quality Assurance (QA), Quality Control (QC), and Quality Improvement (QI) through the processes and the key quality components listed below:

- Project Deliverables & Project Processes: The key project deliverables and processes are subject to quality review.

- Deliverable Quality Standards: The quality standards are the “measures” used to determine a successful outcome for a deliverable. These standards may vary depending on the type of information technology project.

- Customer Satisfaction: The customer satisfaction criteria describe when each deliverable is complete and acceptable as defined by the customer. Deliverables are evaluated against these criteria.

- Quality Control Activities: The quality control activities monitor and verify that the project deliverables meet defined quality standards.

- Process Quality Standards: The quality standards are the “measures” used to determine if project work processes are being followed.

- Stakeholder Expectations: Stakeholder expectations describe when a project process is effective as defined by the project stakeholders. An example is the review and approval of all high-impact changes to the project.

- Quality Assurance Activities: The quality assurance activities that monitor and verify that the processes used to manage and create the deliverables are followed and are effective.

- Quality Improvement: Ensure that quality is constantly improving.

- Roles and Responsibilities: Ensure everyone understands and knows their role in the quality management process.

Development of a Quality Management Plan (QMP)

The project manager develops the QMP but utilizes input from various project team members, including quality managers, stakeholders, team members, and other project personnel. Creating a quality management plan is essential in ensuring that a company always provides high-quality products or services. This detailed document explains how an organization will meet or exceed customer expectations while staying in line with business rules and standards.

- Step 1: Plan QMP Development: Organize an excellent team to plan the development and implementation of the QMP. This will most likely go well if team members work together and talk to each other. This keeps quality as the top goal throughout the project’s lifecycle.

- Step 2: List Goals and Objectives: The first step in making a plan for quality management is to be clear about the project’s goals and scale. This means figuring out who the key players are what they want, and setting quality goals that can be measured. It’s essential to use cross-functional teams to ensure that different points of view and areas of knowledge are considered.

- Identify the customer’s Quality Objectives.

- Help customers express quality expectations in objective, quantitative terms.

- Balance needs and expectations of customers and stakeholders with cost, schedule, and professional standards. Evaluate the costs and benefits of selected quality objectives and the processes to be used to achieve objectives.

- Ensure customer endorsement of all quality objectives included in the Quality Management Plan.

- Step 3: Detail Control Methods and Procedures: Describe the quality control methods used throughout the project’s lifecycle. This includes setting quality standards, making plans for checking and testing, and figuring out who is responsible for what in terms of quality assurance.

- Identify professional standards, including legal, environmental, economic, code, life safety, and health.

- To achieve objectives, develop an effective plan and processes, including quality assurance and quality control procedures. Consider risk/hazard factors and the project’s complexity and adapt processes to provide the requisite level of quality. Document any project variations from the local QMP requirements in the risk management plan.

- Develop performance measure thresholds to ensure agreement on the definition of success relative to Quality Objectives.

- Step 4: Detail Risk Control Strategies: Risk management strategies should be used to find possible quality problems and devise plans to fix them. Regular tracking and reporting systems should also be set up so that progress can be tracked and problems can be fixed quickly.

- Step 5: Write the QMP: This step is best done using a template. A few are provided below, but more can be found online. Remember, the QMP should be a living record that changes as the project progresses.

Quality Management Plan (QMP) Templates

A template is a great place to start when developing a QMP. It provides a consistent foundation for the program manager and team members in developing the plan. It makes sure all key elements of a well-written plan are addressed. An organization should adopt its own QMP template for its programs to provide consistency and meet its particular needs. A few templates are provided below:

-

Template: Sample Quality Management Plan (QMP)

-

Template: IT Project Quality Management Plan (QMP)

-

Template: EPLC Quality Management Plan (QMP)

-

Template: CTDSS Quality Management Plan (QMP)

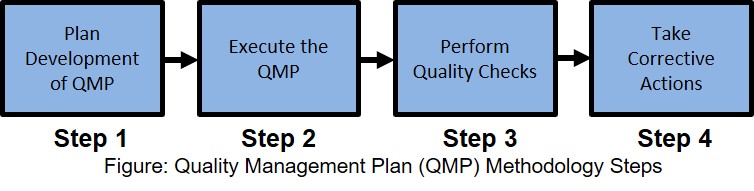

4 Steps of a Quality Management Plan (QMP) Methodology

Step 1: Plan the Development of the QMP

- Identify the customer’s Quality Objectives. Help customers express quality expectations in objective, quantitative terms.

- Identify professional standards, including legal, environmental, economic, code, life safety, and health.

- Balance needs and expectations of customers and stakeholders with cost, schedule, and professional standards. Evaluate the costs and benefits of selected quality objectives and the processes to be used to achieve objectives.

- To achieve objectives, develop an effective plan and processes, including quality assurance and quality control procedures. Consider risk/hazard factors and complexity of the project and adapt processes to provide the requisite level of quality. Document any project variations from the local QMP requirements in the risk management plan.

- Develop performance measure thresholds to ensure agreement on the definition of success relative to Quality Objectives.

- Ensure customer endorsement of all quality objectives included in the Quality Management Plan.

Step 2: Execute the QMP

- Do the work according to the approved Program Management Plan (PMP) and standard operating procedures.

- Project execution is a dynamic process. The program management team must communicate, meet regularly, and adapt to changing conditions. The Quality Management Plan and PMP may require modification to meet project objectives.

- Document in Lessons Learned.

Step 3: Perform Quality Checks

- Perform independent technical review, management oversight, and verification to meet quality objectives with District Quality Management Plans consistently.

- Check performance against the PMP and Customer Quality Objectives performance measures thresholds to verify that performance will accomplish Quality Objectives and to verify the sufficiency of the plan.

- Share findings with all project stakeholders to facilitate continuous improvement.

Step 4: Take Corrective Action if Necessary

- If performance measure thresholds are exceeded, take specific corrective actions to fix the systemic cause of any non-conformance, deficiency, or other unwanted effects.

- Document quality improvements that could include appropriate revisions to the quality management plan, alteration of quality assurance and control procedures, and adjustments to resource allocations.

Quality Management Plan (QMP) Key Roles and Responsibilities

The Program Manager is ultimately responsible for ensuring a project adheres to the QMP, but they are not the only ones. Everyone involved in a project has an active role in ensuring quality activities and functions are addressed. A few of the other members that have a role in the quality management of a program are listed below.

- Organizational Leadership: An organization must ensure quality management is a top priority and that the tools and resources are available.

- Project Manager: Develops the quality management plan and methodology to be followed on a project. Ultimately responsible for quality being met.

- Quality Control Manager: Ensures that all quality management standards are being performed and highlight deficiencies to the PM.

- Members: All project members are responsible for ensuring quality standards, and the quality processes followed are met on a project.

- Stakeholders: Sets the expectations for quality on a project and approves the delivery of that product or service.

- Customers: It also sets the standard for quality.

Top 5 Lessons Learned in Developing a Quality Management Plan (QMP)

- Set the project’s quality standards and goals in a clear way. This means setting clear, measurable quality goals and laying out the steps and standards for figuring out if those goals have been met.

- Include all important people in the process of managing quality. This includes project team members, customers, and anyone else who has a stake in the project’s success.

- Set up a clear plan for how to find, analyze, and solve quality problems. This should include finding the root cause of quality problems, taking steps to fix those problems, and keeping track of and reporting on how well those steps worked.

- Set up a process for continuous improvement to find and fix places where the quality management process could improve. This means that the quality management plan should be looked at often and changed as needed to make sure it stays useful and effective.

- Ensure that the quality management plan is used in all parts of the project. This means putting quality into the planning, execution, monitoring, and control processes of the project and making sure that quality is taken into account at every stage of the project’s lifecycle.

Detailed Components of a Quality Management System (QMS)

The practice of a quality management system is divided into four processes that the QMP must address: Quality Planning (QP), Quality Assurance (QA), Quality Control (QC), and Quality Improvement (QI).

- Quality Planning: Quality Planning is the foundation of our quality management system, encompassing the development of strategies and methodologies to meet customer expectations. Through comprehensive risk analysis, identification of critical processes, and determination of quality objectives, we create a roadmap for success. This involves setting clear quality standards, defining roles and responsibilities, and outlining the necessary resources. Effective quality planning ensures that our projects are well-prepared, reducing the likelihood of errors and optimizing overall performance.

- Quality Assurance (QA): is a monitoring approach that evaluates various aspects of an acquisition project or service to determine if the production process meets the minimum quality standards. QA includes regulation of the quality of raw materials, assemblies, products and components, services related to production, and management, production, and inspection processes. The International Organization for Standards (ISO) defines QA as a part of Quality Management focused on providing confidence that quality requirements will be fulfilled.

- Quality Control (QC): Quality Control is a crucial component of our quality management system, focusing on the identification and correction of defects in products or processes. Through systematic inspections, testing, and measurements, QC ensures that our deliverables meet the specified standards and requirements. By employing statistical methods and control charts, we monitor and control the production process, promptly addressing any deviations to maintain consistency and product excellence.

- Quality Improvement: Quality Improvement is an ongoing effort to enhance processes, products, or services based on feedback, data analysis, and innovation. By implementing corrective and preventive actions, we address root causes of issues, aiming for continual enhancement of quality performance. Quality Improvement involves fostering a culture of innovation and learning and encouraging employees to contribute ideas and solutions. Through regular reviews, feedback loops, and the application of quality improvement methodologies such as Six Sigma or Lean, we strive to raise the bar and exceed customer expectations consistently.

What Quality Managers Need to Know: Key Components of a Quality Management Plan

Quality is the cornerstone of any successful business, and as a quality manager at our esteemed company, I am here to shed light on the essential elements of a Quality Management Plan (QMP). The effective practice of a Quality Management System (QMS) revolves around four core processes: Quality Planning (QP), Quality Assurance (QA), Quality Control (QC), and Quality Improvement (QI). In this blog, we will explore how each of these processes contributes to our commitment to delivering excellence and how they are integrated into the comprehensive framework of a QMP.

Visit: Blog Article

AcqLinks and References:

- Template: IT Project Quality Management Plan (QMP)

- Template: Sample Quality Management Plan (QMP)

- Template: Design-Build Quality Management Plan (QMP) Outline

Updated: 2/2/2024

Rank: G3.3